Minitab Workspace™

The Comprehensive Project Management Solution for the Quality Improvement Process

Minitab Workspace™ is the ultimate toolkit for visualizing, optimizing and mapping company processes better than ever before. It is the dynamic project management solution that combines the essential software tools of a quality improvement process in an integrated and customizable software environment. It is specifically designed to facilitate the planning, organization, implementation and reporting tasks of general development projects, quality improvement projects and projects related to Six Sigma and Lean Six Sigma. With its customizable project workflows, Workspace can be adapted to any company standard or a company standard can be defined regarding the handling of projects.

Areas of Applications

- Quality improvement processes

- Any structured project management

- Six Sigma projects

- Design For Six Sigma (DFSS projects)

- Lean Six Sigma projects

- Kaizen projects

- TRIZ projects

- Continuous improvement projects (CIP)

Lean in Application – Simplifying Your Own Project Work and Management

All tools used in Workspace store important information in the project centrally. This means that changes can be made quickly with a single action. Once information has been entered, it can be accessed directly elsewhere. For example, results from a flow chart or brainstorming session can be derived directly into an FMEA. Associated documents and files can be saved directly in the project or linked to it.

Over 100 of the Most Common Project Tools Individually Customized

With the installation of Minitab Workspace, the typical project tools of various solution approaches are available. These can be used as part of any project as well as on their own. The results of all tools can be exported directly as PDF files.

It is also easy to create your own tools. Existing tools can also be adapted in order to expand them, streamline them or adapt them to your own corporate identity. All new developments can then be saved directly as a template and made centrally available to the user group.

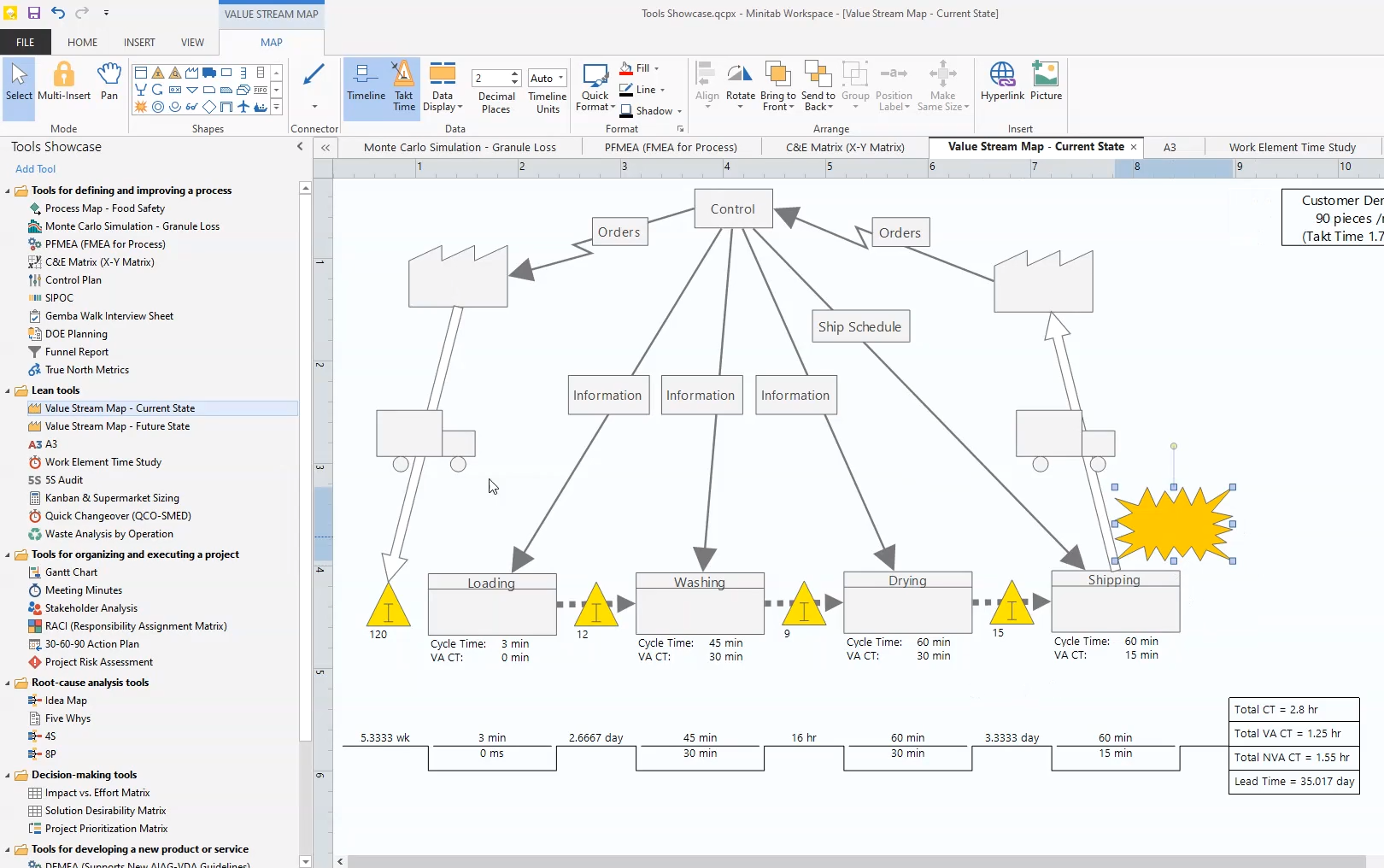

| Value Stream Mapping | Monte Carlo Simulation | FMEA |

|---|---|---|

| The movement of materials and data through a company is visualized. The modernization of processes creates added value that meets customer expectations. | Monte Carlo simulation is used to describe, understand and optimize a product or process. | Potential causes of a product or process failure are identified, the resulting effects are forecast and the actions required to counteract these effects are prioritized. |

| Quality Function Deployment | Brainstorming Tools | Process Mapping |

| With the fully integrated functions Pairwise Comparison Matrix, Houses of Quality and Design Scorecards, a smooth flowdown of requirements can be ensured. | Fishbone diagrams and idea maps can be used to identify all relevant elements of a process and determine the scope of complex projects more precisely. | The creation of high-quality and detailed flowcharts helps users to understand and communicate all activities in a process. |

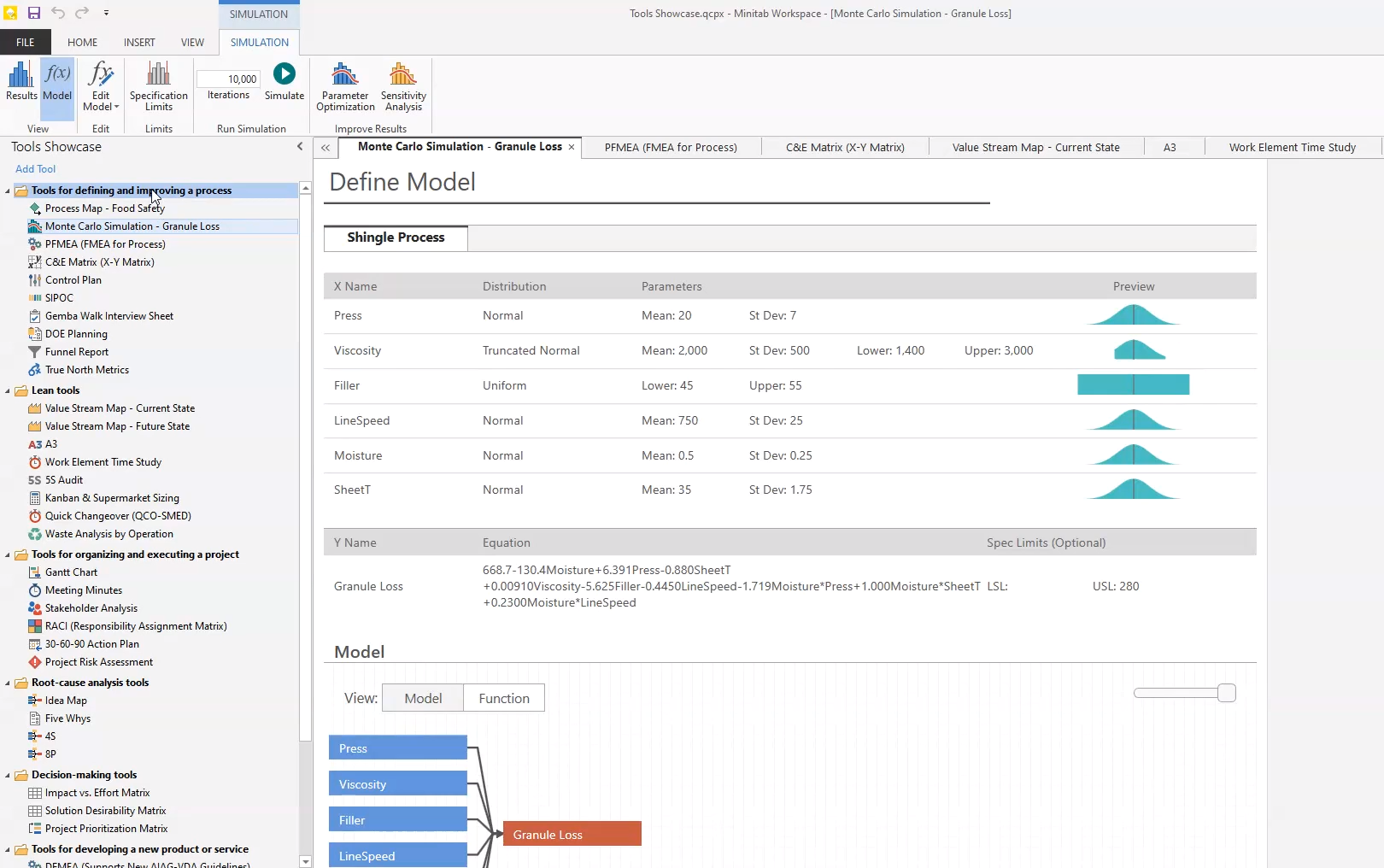

Monte Carlo Simulation

The Monte Carlo simulation in Minitab Workspace is a powerful tool for product and process improvement. Realistic models can be easily created or transferred from Minitab (from regression, ANOVA or DoE). Simulation results are displayed clearly. The integrated parameter optimization allows you to find the optimal settings for input parameters. The sensitivity analysis has an intelligent, interactive design that can be used to examine the effect of an input’s variation on the output’s variation. In addition to the optimization of models directly based on waste, you can also define specification limits (statistical tolerance analysis).

Integration of Minitab

With the combination of Minitab (the statistical analysis software) and Workspace, team members (e.g. Black Belts, Green Belts, ...) of improvement projects get a complete solution to run projects with maximum efficiency, as all essential data is kept in a unified, multi-user environment. Projects can be started with the help of tools in Workspace. They can maintain the overview and use Minitab to analyse data precisely at critical points, perform measurement system analyses (Gage R&R), process capability analyses and DoE (Design of Experiments). Both software packages together optimize every quality campaign.

A Platform for Mapping all Conceivable Solutions

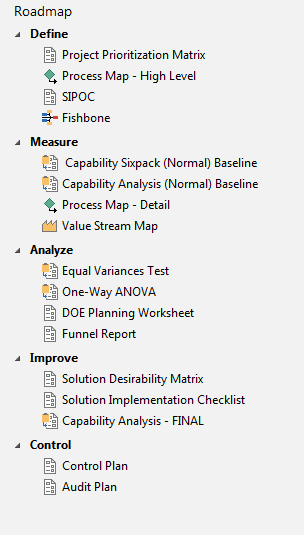

Whether Six Sigma, Design For Six Sigma (DFSS), Lean, Kaizen, 8D, TRIZ, Continuous Improvement Projects (CIP) or a simple "Just Do It" project - with the roadmap in Workspace, projects can be divided into phases in such a way that they follow the corresponding philosophy. In addition to numerous specifications, the roadmap can also be individually adapted to the company's own philosophy and made available as a template. This enables Workspace to cover all conceivable solution approaches.

Further details about Lean Six Sigma, Design For Six Sigma, Lean

Project Management with a Common Thread, the Roadmap

Roadmaps™ can be used to structure the approach in the projects and thus provide a common thread. This allows the workflow in each project to be predefined and adapted or predefined to company-specific standards. There are several such predefined roadmaps (all of which can be modified), including some for the DMAIC cycle used in Six Sigma quality strategies, for example. Data entered in one tool is available for the entire project. This guarantees fast work with consistent data and fewer errors. Most tools can be customized to create your own templates.

Project Management as a Team Project

Minitab Workspace makes it possible to effectively exchange information within the project team and to standardize and thus simplify project processes and their documentation. The software tools are used in a uniform manner and can communicate with each other. To ensure that team communication runs smoothly, roles and rights can be assigned so that only the components are processed that are required by the respective person.

Project Management as an Overall Concept

Process visualization, the creation of forms or the organization of meetings - to name just a few tasks - follow an overall concept that each company can define for itself. All elements and data belonging to the project are stored in a project file. This approach saves time in the administration and organization of the improvement process.

Not all product information on our website is available in English, but our sales experts are happy to assist you. Please schedule a consulation appointment via email at